We have an experimental fish farm. Tilapia. It’s aquaponics, so there’s a plant fertilizer component too.

This is the final design, the grow-out tank system. It consists of a 250 gallon fish tank on the left and on the right is a 55 gallon drum for the biomedia filter.

What you see cost a hundred bucks, for the “tote” on the left, a major Craigslist score, we got two of them. The 55 gallon drum was free, from a miner we expedite for, we got two of them.

We have all the materials to complete the system we designed after a literature survey and experience of our own.

For now, we bought 94 tiny little tilapia, like micro-dots. This took seven weeks to accomplish, an an algae diet, which is pretty amazing:

On the left is "before" and on the right "after". Now they are just starting to take the first pelletized feed.

Everyone is in a 61 gallon system at the moment, consisting of a 55 gallon tank and 6 gallons in the filter system, which we designed ourselves. All the electric is on one circuit, I wired a separate circuit from the breaker to this system so it was on its own fuse.

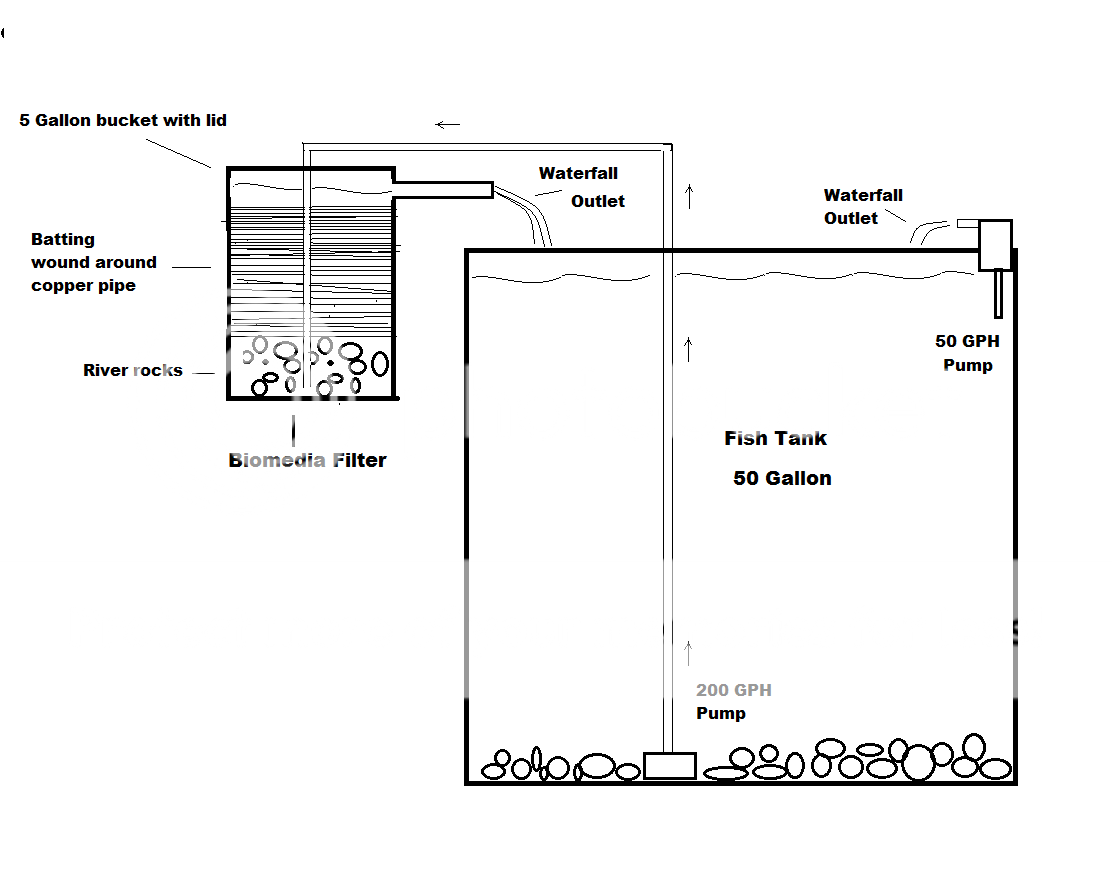

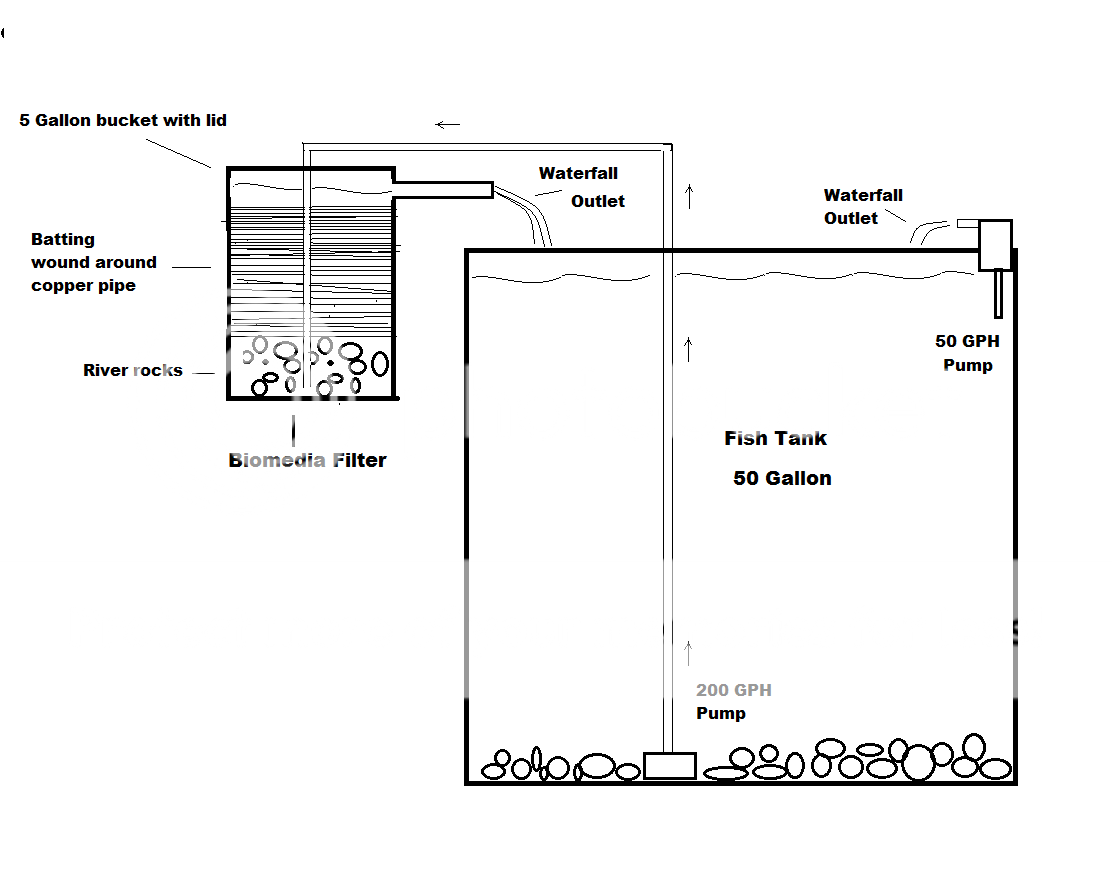

This is the schematic which is scalable.

We have a unitized system of fish tank and biomedia filter, with a way to draw off the fertilizer.

The main tank has a spigot at the bottom to draw off solids. The biomedia filter can be cleaned and the finer fertilizer captured.

What is different about our system is that we have two media (rocks and batting) and combine functions that would require three tanks instead of two.

The fish tanks have big rocks at the bottom. They host media that like to eat fish poopies. But it also allows solids to accumulate and be drawn off now and then by the spigot at the bottom.

The pump in the bottom of the fish tank forces water up a line and then down to the bottom of the filter tank, which has rocks in the bottom, same reason. The media in our case is batting we got 40% off at the fabric store. It is wound tight around a copper line in the center. The water has to force its way through a lot of batting where it comes out at the top crystal clear.

The filtered water goes out a pipe and makes a waterfall into the 55 gallon tank. You need it to be a waterfall so that it oxygenates the water. Then you don’t need an aerator. This uniseal joint, and trimming a little 5 gallon bucket with a lid makes a 6 gallon filter system for the 55 gallon tank:

The batting worked so good we bought the fabric store out, my God the entire 710 gallon system cost $42 total for the media. Might as well be free, the pet store sells goldfish bowl sand for that price.

We have another 40 gallon system we are about to start up inside, it is getting a little crowded in the one above. We are going to put the smallest fish in the 40 gallon system. We are keeping the fish inside the cabin as long as we can, so we do not have to heat the main 610 gallon system out in the shop yet.

So basically we have a 100 gallon indoor system and a 600 gallon “ outdoor” system. Outdoors, there are two tank/filtration systems that are each designed for 50 fish. So 100 fish outdoors, 1.5 lbs. each, although they can grow a lot bigger. Inside, 150 little fish if we want to run it full bore.

The kids logged, skidded, and peeled timbers for a loft in our shop to house the outdoor tanks:

The timbers were notched to fit, then bolted together, and bolted to the log walls and purlins with lag bolts. All but two bolts scrounged up on the homestead.

That was the start of store-bought lumber, we can mill but I have leftover 2x6's and plywood from construction contracting. In the very first picture, my son is standing up in the finished loft with the tanks.

I’ll talk about electric use, feed costs, and such next time. But a little bit about why we are doing this.

We are going to sell live fish in the Philippines. We are learning the whole thing from breeding through meat production and “Aquaponics” (the fertilizer is for plants) for now. We want to run things at a scale commensurate with a real experimental farm, over 200 fish in various stages.

Protein production can be compared on efficiency grounds, the conversion of feed in pounds to meat in pounds. For beef, it is common to have 8 lbs. of feed required for 1 lb. of meat. For pork, about 2.5 lbs. of feed per lb. of pork. Fowl will get you down to 2:1 and turkeys even below 2:1.

These tilapia require 1.1 lbs of food to produce 1 lb. of fish, it is incredible. Plus you get the fertilizer, it is as valuable as bat guano. While the government schools are teaching kids PC rhetoric, these kids helped build a fish farm. It is a tautology to say it is homeschool because the kids never leave our sides, everything we do is homeschool.

Small percentage shifts in diet, from beef to fish, mean incredible relief on the earth’s resources. There is way too much pressure on the wild stocks around the Philippines, yet the ocean can support vastly more fish.

I saw a system for sale that was over $4,000 on the internet, I went looking for fun. We haven’t spent $400 yet and ours will handle order of magnitude more fish. Our filtration systems are absurdly large. I don’t care, the components were nearly free.

I am putting together a spreadsheet that is going to work out the cost per pound of fish. The grow-out stage is where you can really blow it on feed costs. But we have read a LOT of peer-review literature on this and are going to do some experimentation ourselves before finalizing our grow-out feed recipe. We will try to produce some of it ourselves, depending on how successful our experiments are.

This is the final design, the grow-out tank system. It consists of a 250 gallon fish tank on the left and on the right is a 55 gallon drum for the biomedia filter.

What you see cost a hundred bucks, for the “tote” on the left, a major Craigslist score, we got two of them. The 55 gallon drum was free, from a miner we expedite for, we got two of them.

We have all the materials to complete the system we designed after a literature survey and experience of our own.

For now, we bought 94 tiny little tilapia, like micro-dots. This took seven weeks to accomplish, an an algae diet, which is pretty amazing:

On the left is "before" and on the right "after". Now they are just starting to take the first pelletized feed.

Everyone is in a 61 gallon system at the moment, consisting of a 55 gallon tank and 6 gallons in the filter system, which we designed ourselves. All the electric is on one circuit, I wired a separate circuit from the breaker to this system so it was on its own fuse.

This is the schematic which is scalable.

We have a unitized system of fish tank and biomedia filter, with a way to draw off the fertilizer.

The main tank has a spigot at the bottom to draw off solids. The biomedia filter can be cleaned and the finer fertilizer captured.

What is different about our system is that we have two media (rocks and batting) and combine functions that would require three tanks instead of two.

The fish tanks have big rocks at the bottom. They host media that like to eat fish poopies. But it also allows solids to accumulate and be drawn off now and then by the spigot at the bottom.

The pump in the bottom of the fish tank forces water up a line and then down to the bottom of the filter tank, which has rocks in the bottom, same reason. The media in our case is batting we got 40% off at the fabric store. It is wound tight around a copper line in the center. The water has to force its way through a lot of batting where it comes out at the top crystal clear.

The filtered water goes out a pipe and makes a waterfall into the 55 gallon tank. You need it to be a waterfall so that it oxygenates the water. Then you don’t need an aerator. This uniseal joint, and trimming a little 5 gallon bucket with a lid makes a 6 gallon filter system for the 55 gallon tank:

The batting worked so good we bought the fabric store out, my God the entire 710 gallon system cost $42 total for the media. Might as well be free, the pet store sells goldfish bowl sand for that price.

We have another 40 gallon system we are about to start up inside, it is getting a little crowded in the one above. We are going to put the smallest fish in the 40 gallon system. We are keeping the fish inside the cabin as long as we can, so we do not have to heat the main 610 gallon system out in the shop yet.

So basically we have a 100 gallon indoor system and a 600 gallon “ outdoor” system. Outdoors, there are two tank/filtration systems that are each designed for 50 fish. So 100 fish outdoors, 1.5 lbs. each, although they can grow a lot bigger. Inside, 150 little fish if we want to run it full bore.

The kids logged, skidded, and peeled timbers for a loft in our shop to house the outdoor tanks:

The timbers were notched to fit, then bolted together, and bolted to the log walls and purlins with lag bolts. All but two bolts scrounged up on the homestead.

That was the start of store-bought lumber, we can mill but I have leftover 2x6's and plywood from construction contracting. In the very first picture, my son is standing up in the finished loft with the tanks.

I’ll talk about electric use, feed costs, and such next time. But a little bit about why we are doing this.

We are going to sell live fish in the Philippines. We are learning the whole thing from breeding through meat production and “Aquaponics” (the fertilizer is for plants) for now. We want to run things at a scale commensurate with a real experimental farm, over 200 fish in various stages.

Protein production can be compared on efficiency grounds, the conversion of feed in pounds to meat in pounds. For beef, it is common to have 8 lbs. of feed required for 1 lb. of meat. For pork, about 2.5 lbs. of feed per lb. of pork. Fowl will get you down to 2:1 and turkeys even below 2:1.

These tilapia require 1.1 lbs of food to produce 1 lb. of fish, it is incredible. Plus you get the fertilizer, it is as valuable as bat guano. While the government schools are teaching kids PC rhetoric, these kids helped build a fish farm. It is a tautology to say it is homeschool because the kids never leave our sides, everything we do is homeschool.

Small percentage shifts in diet, from beef to fish, mean incredible relief on the earth’s resources. There is way too much pressure on the wild stocks around the Philippines, yet the ocean can support vastly more fish.

I saw a system for sale that was over $4,000 on the internet, I went looking for fun. We haven’t spent $400 yet and ours will handle order of magnitude more fish. Our filtration systems are absurdly large. I don’t care, the components were nearly free.

I am putting together a spreadsheet that is going to work out the cost per pound of fish. The grow-out stage is where you can really blow it on feed costs. But we have read a LOT of peer-review literature on this and are going to do some experimentation ourselves before finalizing our grow-out feed recipe. We will try to produce some of it ourselves, depending on how successful our experiments are.

via International Skeptics Forum https://ift.tt/2K0qO0b

Aucun commentaire:

Enregistrer un commentaire